Insights from Next Chapter

Proven Additive Manufacturing Solutions & Resources

Next Chapter Features

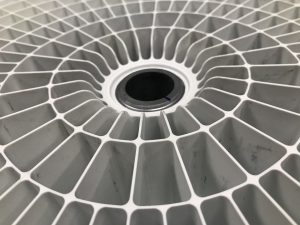

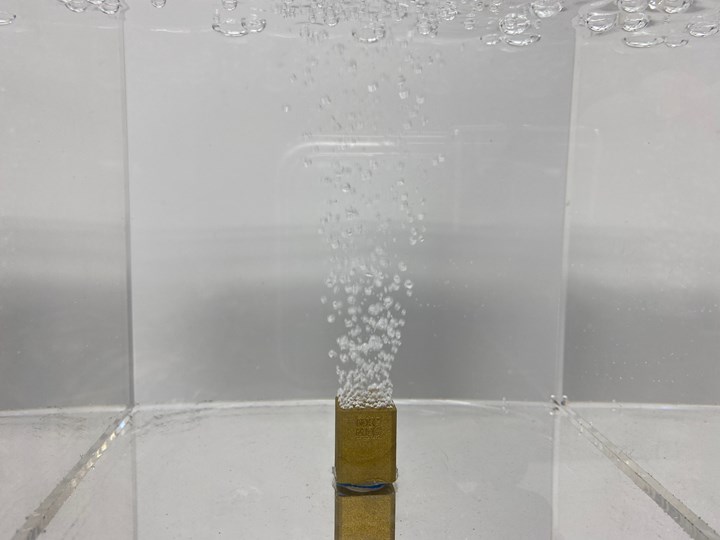

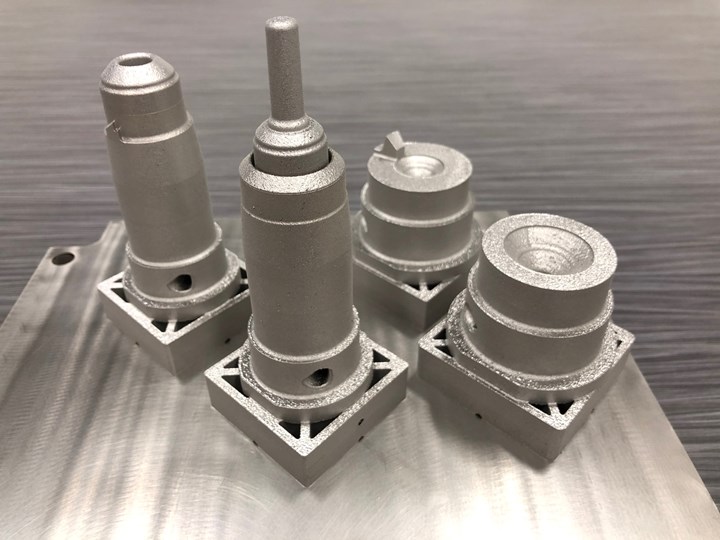

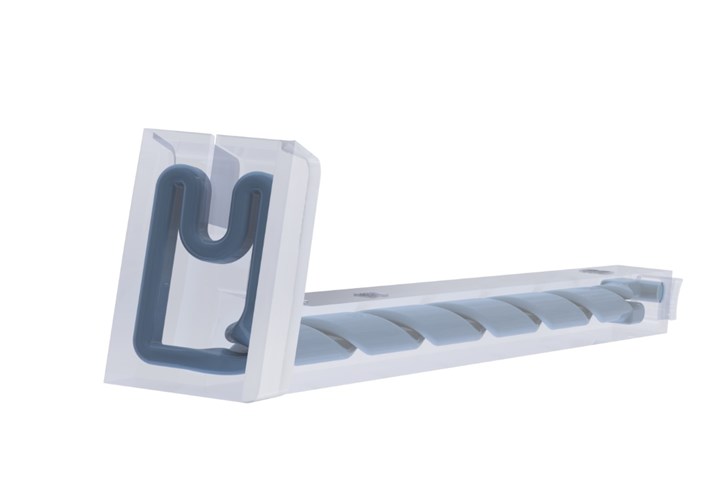

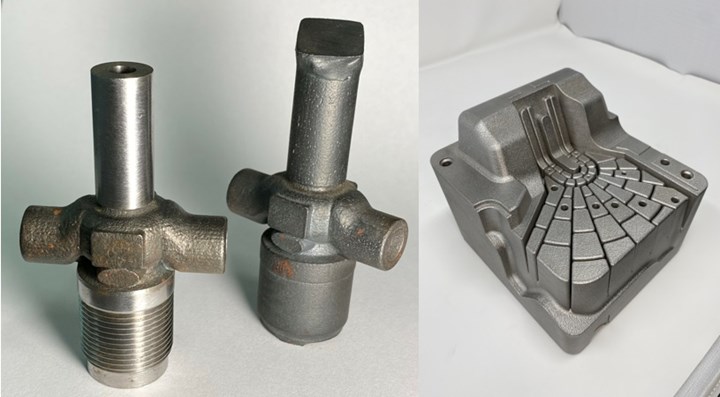

Additive Tooling Goes Beyond Conformally Cooled Inserts to Simplify the Mold Build Process

Go Check Out Our YouTube

NXCMFG YouTube

4 Videos

0:16

0:16

0:16

0:16

Join Our Newsletter

Stay up-to-date on the latest news and innovations from Next Chapter. Enter your email below to join our mailing list.

4 Easy-to-Avoid 3D

Printed Tooling Mistakes

Not ready to build yet? Download our guide, 4 Easy-to-Avoid 3D Printed Tooling Mistakes, and learn how to avoid costly pitfalls before your next project starts.