Turning the Page on Conventional Manufacturing

Next Chapter Manufacturing serves moldmakers, plastic processors, and OEMs across the world as they revolutionize their manufacturing and production process.

Manufacturing Isn’t Slowing Down.

Neither Should You.

While your competitors push ahead, outdated tooling and production delays keep you stuck, forcing you to squeeze more life out of aging machines or navigate additive manufacturing without the right expertise. Meanwhile, your customers keep moving, sometimes going straight to your competition.

It’s time to turn the page on conventional manufacturing.

Our Capabilities

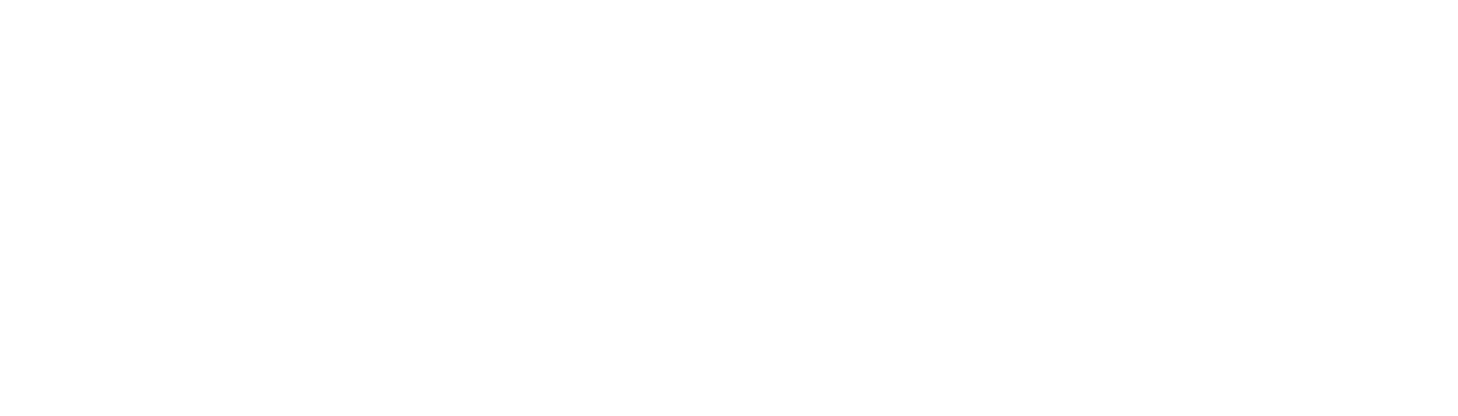

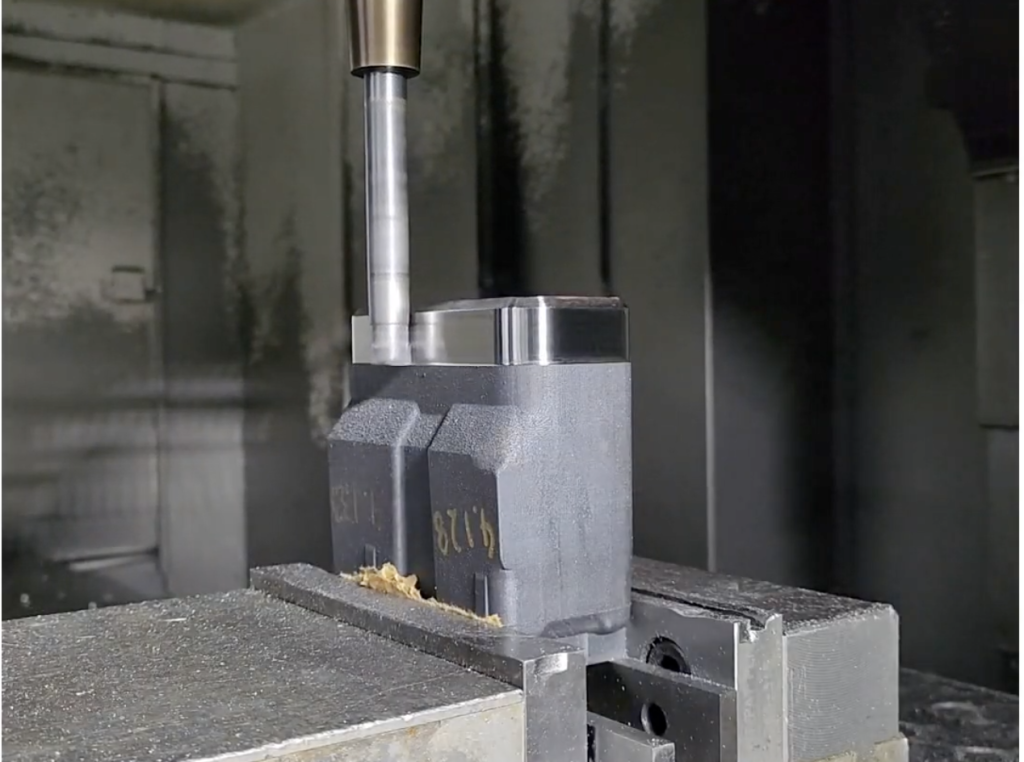

Conformal Cooling

Conformal Cooling

Our conformal cooling technology uses additive manufacturing to engineer cooling channels that follow part geometry, unlocking faster cycle times, better part quality, and unmatched efficiency in plastic injection molding.

Venting

Venting

Our advanced venting technology delivers precision-engineered, porous steel structures that evacuate gas efficiently without compromising part integrity, solving defect-prone areas and elevating tool performance across millions of cycles.

Who We Serve

Moldmakers

We partner with moldmakers to deliver precision-engineered, additive manufactured tooling components, like conformal cooled inserts, sprue bushings, and venting solutions, that boost mold performance, extend tool life, and cut cycle times without compromise.

Plastics Processors

We help plastics processors maximize efficiency and part quality with advanced tooling solutions, like conformal cooling, precision venting, and rapid-turnaround inserts, engineered to reduce cycle times, solve defect-prone areas, and keep production running at peak performance.

OEMS and Tier 1s

We deliver high-performance, custom-engineered tooling solutions that help OEMs and Tier 1s accelerate time-to-market, improve part consistency, and meet demanding production targets backed by additive expertise and proven results across critical applications.

Our Purpose

At Next Chapter Manufacturing, we are committed to writing the next chapter in tooling and high-volume production by challenging how plastics are formed through innovative tooling solutions. Our mission is to add to our clients’ success by producing optimized tooling that makes quality parts in the most efficient cycles possible.

We value:

- Innovation: We continually seek to challenge the status quo and develop cutting-edge solutions that redefine industry standards.

- Collaboration: We believe in working closely with our clients and partners to achieve shared success through open communication and teamwork.

- Integrity: We uphold the highest ethical standards, ensuring transparency, honesty, and accountability in all our interactions.

- Excellence: We strive for superior quality in every aspect of our work, from design to delivery, to exceed client expectations.

- Sustainability: We are dedicated to environmentally responsible practices that promote long-term industry and community well-being.

By embodying these values, NXCMFG continues to lead in providing advanced tooling solutions that empower our clients and drive the industry forward.

4 Easy-to-Avoid 3D

Printed Tooling Mistakes

Not ready to build yet? Download our guide, 4 Easy-to-Avoid 3D Printed Tooling Mistakes, and learn how to avoid costly pitfalls before your next project starts.

Trust the Additive Manufacturing and 3D Printing Experts

Ready to write the next chapter in your tooling? Partner with Next Chapter Manufacturing to engineer smarter, faster, and more reliable solutions that move your business forward.