Injection Mold Venting Solutions

Innovative mold venting that solves defects at the source with customizable, self-cleaning pins and engineered solutions.

Unlock the Next Chapter of Part Quality

With Innovent Technology

Say goodbye to gas traps, short shots, and mold maintenance headaches. Whether it’s InnoVent pins or integrated custom vent inserts, Next Chapter delivers custom proprietary injection mold venting systems that form better parts from day one.

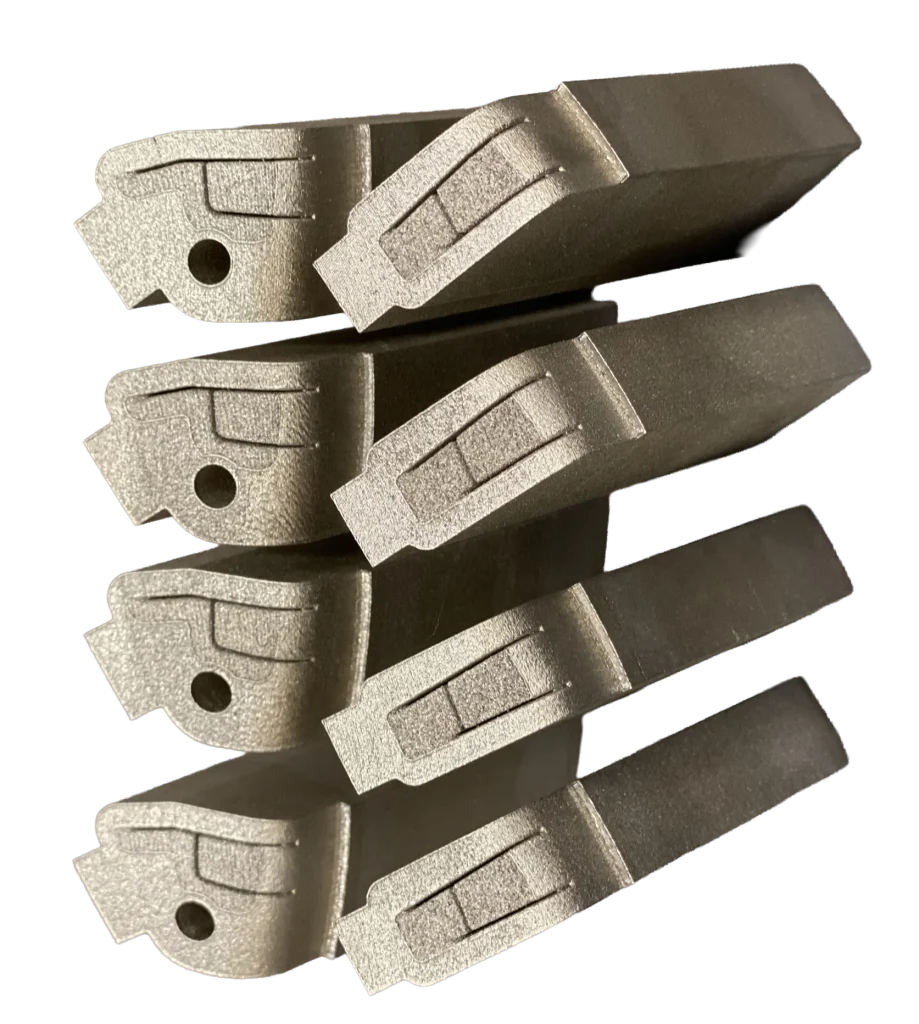

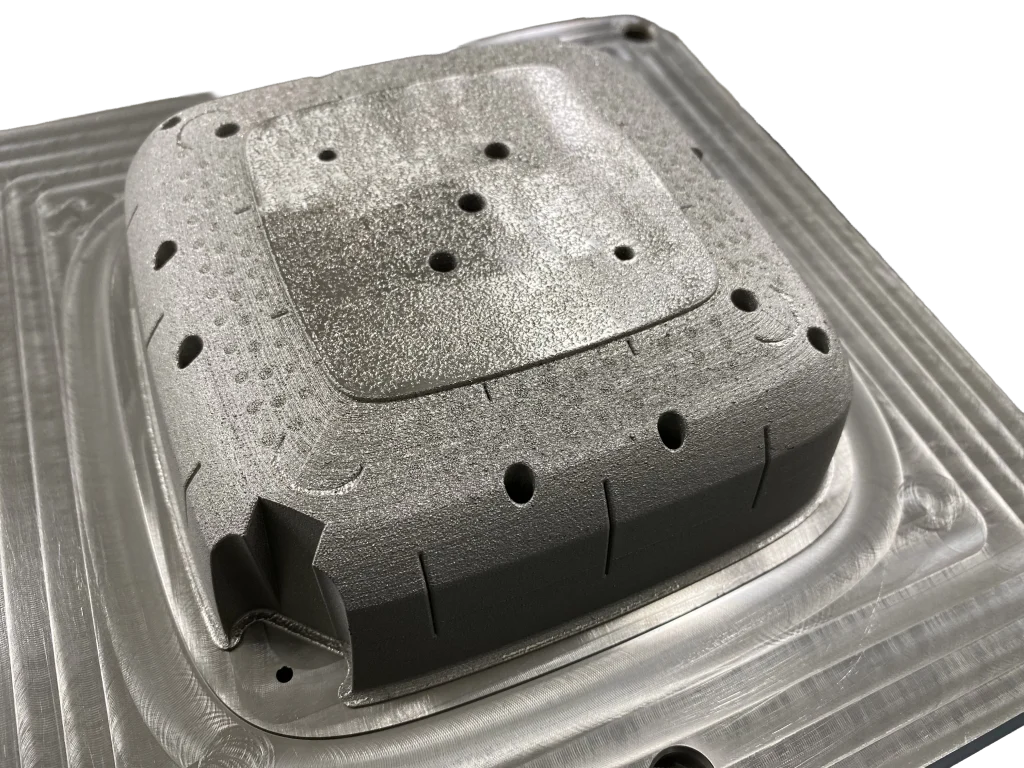

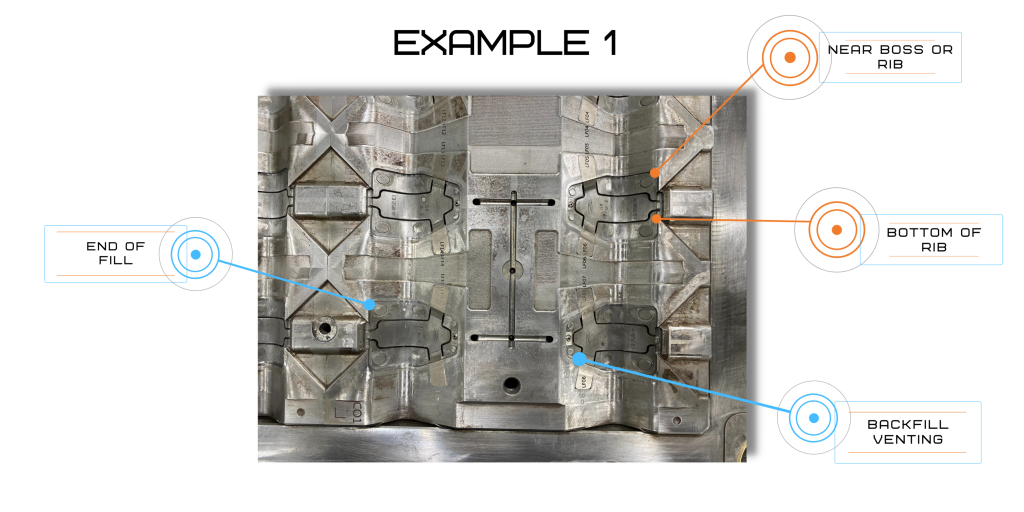

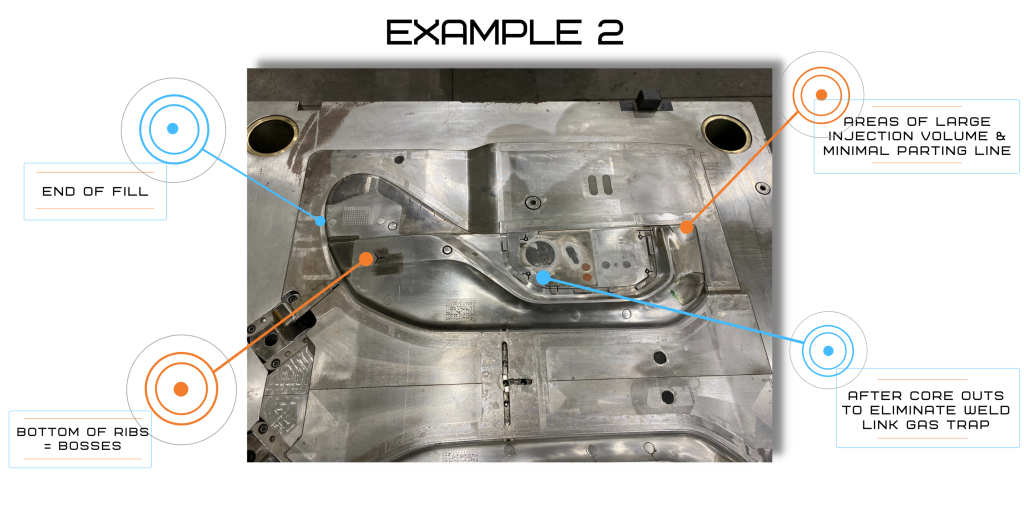

Injection Mold Venting in Action

Proper gas dissipation ensures that your molds keep working at full capacity for your production line, shot after shot. Our injection mold venting design is intuitive and perfectly calculated to suit your needs.

A Dual Approach to Smart Venting

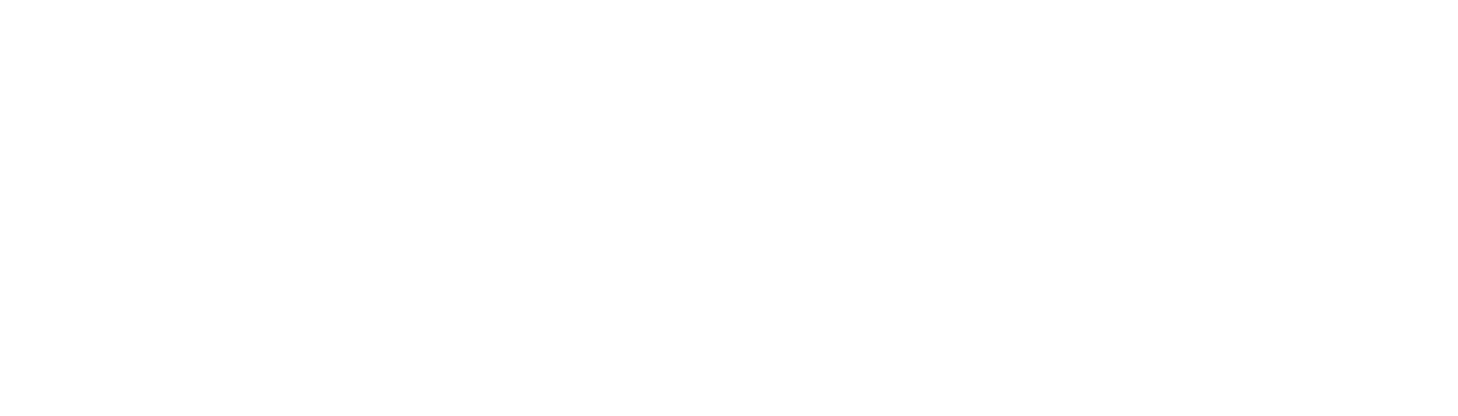

InnoVent Pins

InnoVent Pins

Precision-engineered, solid-state pins that offer self-cleaning functionality, ultra-low maintenance, and customizable geometries to target specific venting issues. Best for tight-tolerance parts in medical, consumer, packaging, and automotive applications.

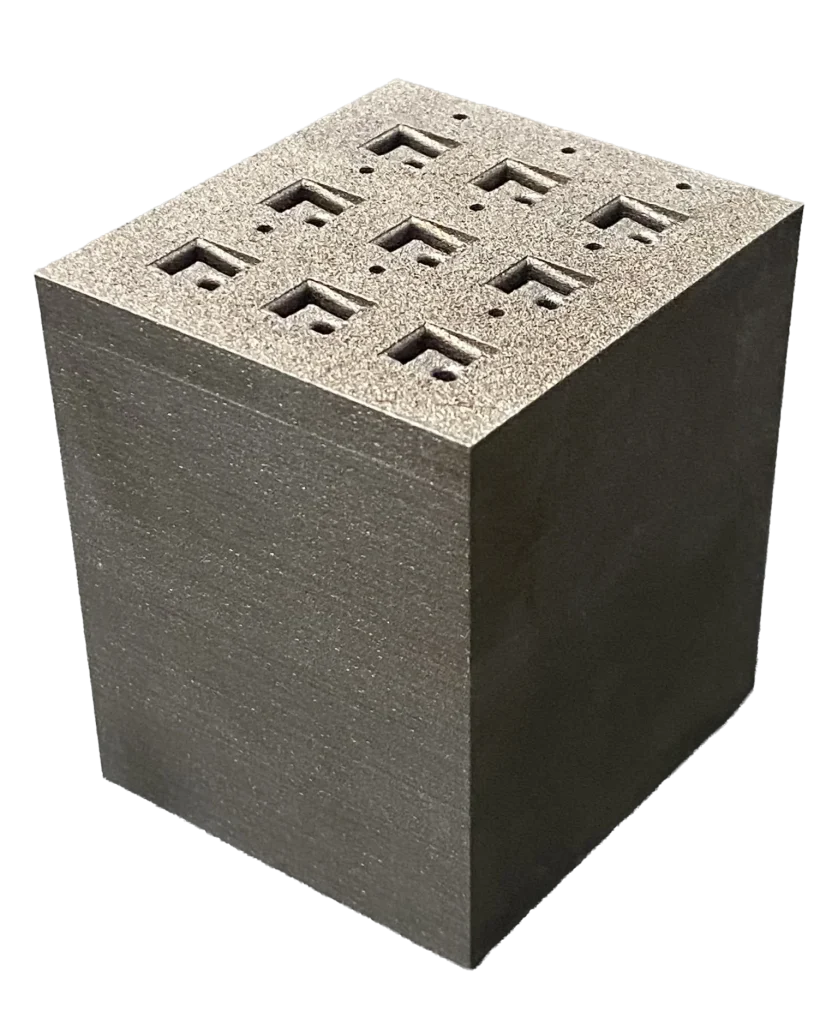

Custom Mold Venting Solutions

Custom Mold Venting Solutions

From engineered porous steels to strategic vent placement, our venting technology improves gas evacuation during fill, solving common molding defects before they occur.

Engineered for Better Parts. Period.

- InnoVent Pins are built to be placed exactly where the issue is, any size, any shape. They improve part quality, especially in intricate or high-performance molds.

- Our one-piece pins don’t clog and only require ultrasonic cleaning, delivering long-term reliability with minimal downtime.

-

Proprietary designs offer self-cleaning functionality, reducing maintenance time and production halts.

Before

After

Performance that Pays Off

- Eliminate short shots, burns, voids, and other venting-related defects.

- Reduce scrap and rework, especially critical in regulated industries like medical and automotive.

- Increase tool life and maintain mold health with smart, breathable designs.

- 10-15x more venting with InnoVent pins.

- 1 million shot guarantee.

Built For You

Every mold is different. Every venting challenge is unique. That’s why next chapter engineers the most efficient solution possible.

- Fully customizable pin and vent designs

- Tailored to your mold geometry and part requirements

- Our additive capabilities mean you get vent solutions in days, not weeks.

Application

FAQs

Will I need to replace all of the standard pins in my mold?

No, a simple mold will only need one InnoVent Pin. A more complex mold with 100 pins typically requires only 2-3 InnoVentPins.

How Fast Can They Be Delivered?

This is an off-the-shelf part. You can place your order today and have it tomorrow!

How Can InnoVent Pins Reduce My Costs?

By eliminating scrap due to defects, reducing labor requirements, and mitigating material waste, Next Chapter’s InnoVent Pins provide considerable ROI.

How Can InnoVent Pins Preserve My Molds?

Air pressure is largely responsible for damaging the mold over time. Our carefully engineered InnoVent Pins reduce wear and tear on the mold, which means your molds last longer and require less maintenance.

Will the InnoVent Pins Clog and Require Maintenance?

No, InnoVent Pins are capable of 10 to 15 times the amount of venting as traditional venting solutions, which means they won’t clog. It’s a low-maintenance solution!

Injection Mold Venting in Action

Proper gas dissipation ensures that your molds keep working at full capacity for your production line, shot after shot. Our injection mold venting design is intuitive and perfectly calculated to suit your needs.

Let’s Solve Your Toughest Venting Challenges

Contact Next Chapter today to design an injection mold venting solution that delivers cleaner parts, faster cycles, and zero defects.