Tooling That Transforms Production

At Next Chapter Manufacturing, we’re redefining what’s possible in injection mold tooling. We know the pressures you face, like cycle time, part quality, downtime, and thermal control. That’s why we don’t just print tooling. We engineer smarter solutions.

Leveraging our proprietary InnoVent technology and expertise in conformal cooling, we create precision-engineered tools that run cooler, cycle faster, and last longer.

Tooling Applications

Packaging

Packaging

Precision tooling with conformal cooling cuts cycle times and improves part consistency, which is ideal for high-volume packaging applications where speed and uniformity drive profitability.

Automotive

Automotive

Engineered molds that stand up to aggressive production demands. Our tooling optimizes thermal control for complex geometries, enabling tighter tolerances, faster cycles, and reduced scrap in automotive components.

Consumer Products

Consumer Products

From sleek housings to functional parts, our tooling delivers cosmetic precision and structural integrity, supporting brands that demand both performance and aesthetic perfection at scale.

Medical

Medical

ISO 13485-certified tooling designed for the strict demands of medical manufacturing. We deliver clean, consistent molds that produce high-tolerance, high-performance parts for surgical and diagnostic applications.

Awards and Certifications

- ISO 13485:2016

- ITAR-compliant

- Federal Firearms License Class 07

- SOT 02

Tooling Services

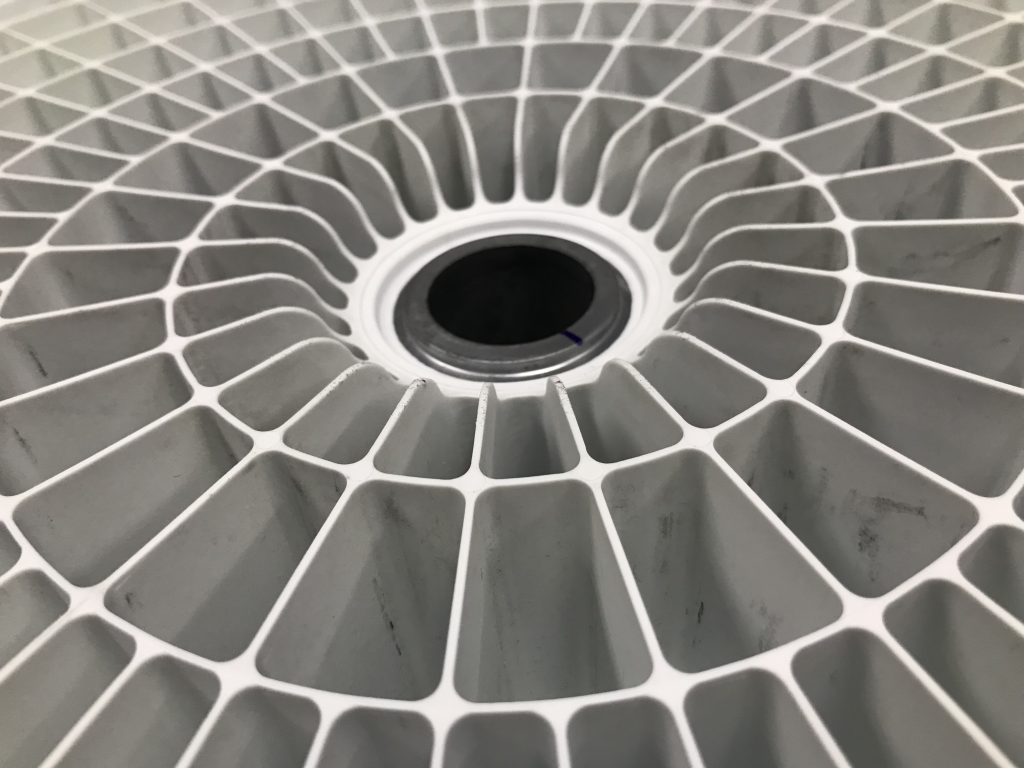

Conformal Cooling

Conformal Cooling

Internal cooling channels are designed directly into the mold, reducing cycle times by up to 30% and improving part consistency without compromising tool integrity.

InnoVent™ Technology

InnoVent™ Technology

Our proprietary thermal management system optimizes heat dissipation and material flow, extending tool life and minimizing defects, especially in high-cavity or complex molds.

Simulation

Simulation

Improve part quality and reduce defects with expert 3D printing analysis, including thermal and mold flow simulations built for performance.

Design Engineering

Design Engineering

Next Chapter Manufacturing transforms the engineering design process with innovative solutions for streamlined, efficient product development.

Our Tooling Advantages

At Next Chapter Manufacturing, every tool is engineered for performance. We combine decades of real-world experience with advanced additive manufacturing to deliver tooling that simply outperforms the status quo. Here’s what sets our solutions apart:

-

Additive-First Engineering

Our design-for-additive approach unlocks geometries and venting patterns impossible with traditional machining, allowing smarter, lighter, and more efficient tooling. -

Million-Shot Guarantee

Backed by materials we’ve tested, tortured, and proven in production. Every tool comes with our industry-first million-shot performance guarantee. -

Rapid Lead Times

Thanks to our open architecture systems and in-house optimization, we deliver production-ready tooling in days—not weeks so you can meet aggressive timelines without sacrificing quality.