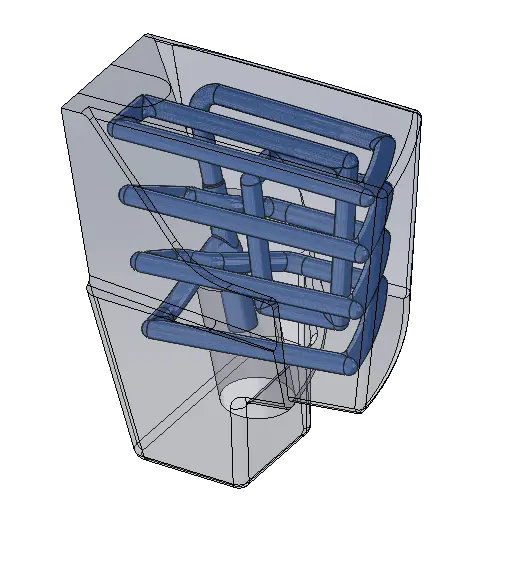

Conformal Cooling Solutions

Leverage conformal cooling through 3D printing to cut cycle times and improve part quality.

Precision-Engineered Cooling Solutions for Enhanced Mold Performance

At Next Chapter, we’re redefining how plastics are molded by integrating conformal cooling with 3D printing into innovative tooling solutions. Our approach ensures uniform cooling, reduces cycle times, and enhances part quality, all tailored to your specific molding challenges.

Why Conformal Cooling and 3D Printing Matters

Traditional cooling channels are limited to straight lines, often failing to reach complex geometries within a mold. This can lead to uneven cooling, resulting in warpage, sink marks, and longer cycle times. Conformal cooling channels, designed to follow the intricate contours of the mold, address these issues by providing uniform cooling throughout the part.

Benefits of Conformal Cooling

- Reduced Cycle Times: Accelerate production by reducing cycle time 20-80%.

- Enhanced Part Quality: Achieve better dimensional stability and eliminate warp.

- Energy Efficiency: Lower energy consumption due to optimized cooling.

- Extended Tool Life: Uniform temperature distribution reduces thermal stress and steel wear on molds.

The Next Chapter 3D Printing Advantage

Using advanced metal additive manufacturing, Next Chapter designs and produces conformal cooling channels that are impossible to achieve with conventional machining. This technology allows for:

- Complex Geometries: Cooling channels that conform precisely to part contours.

- True Tool Steels: Our speciality is printing actual tool steels that outperform other common 3D printing materials.

- Decades of Experience: While others are just getting into additive or employing unproven new technologies, Next Chapter has the experience to produce predictable results every time—guaranteed.

Tailored Solutions for Your Industry

Whether you’re in automotive, medical, consumer goods, or packaging, Next Chapter’s conformal cooling solutions are customized to meet your industry’s specific requirements. Our team collaborates with you to design cooling strategies that enhance performance and efficiency.

Additive Manufacturing in action with Conformal Cooling

Traditional cooling methods won’t solve tomorrow’s molding challenges. Next Chapter is already there solving tomorrow’s challenges with conformal cooling inserts engineered and produced with additive manufacturing technology.

Partner with Us

Ready to improve your molding process with conformal cooling and 3D printing? Contact us today to discuss how our innovative tooling solutions can benefit your production.