Additive Manufacturing for Every Industry

Explore how Next Chapter is helping industries like defense, surgical, and tooling become more efficient with additive manufacturing.

From Defense to Surgical, Let’s Make the World More Efficient

Manufacturing isn’t slowing down, and you can’t afford to lag behind in your industry.

At Next Chapter, we want to build the most efficient world possible through faster cycles, smarter processes, and greater reliability. And when you have access to the efficiency and affordability of additive manufacturing, the world is safer, your patients are healthier, and your line operates smarter.

Industries We Serve

Defense

Defense

We support the defense industry by creating advanced suppressors built to meet specialized needs, like handling 8,000 flawless rounds without cleaning. Powered by TruPore technology, our suppressors reduce heat, improve durability, and cut maintenance time.

Surgical

Surgical

We engineer cutting-edge medical components, including bone-integrated implants and high-performance surgical tools featuring TruPore technology. By leveraging advanced additive manufacturing, we create lighter, stronger, and more efficient designs, reducing lead times and elevating surgical performance.

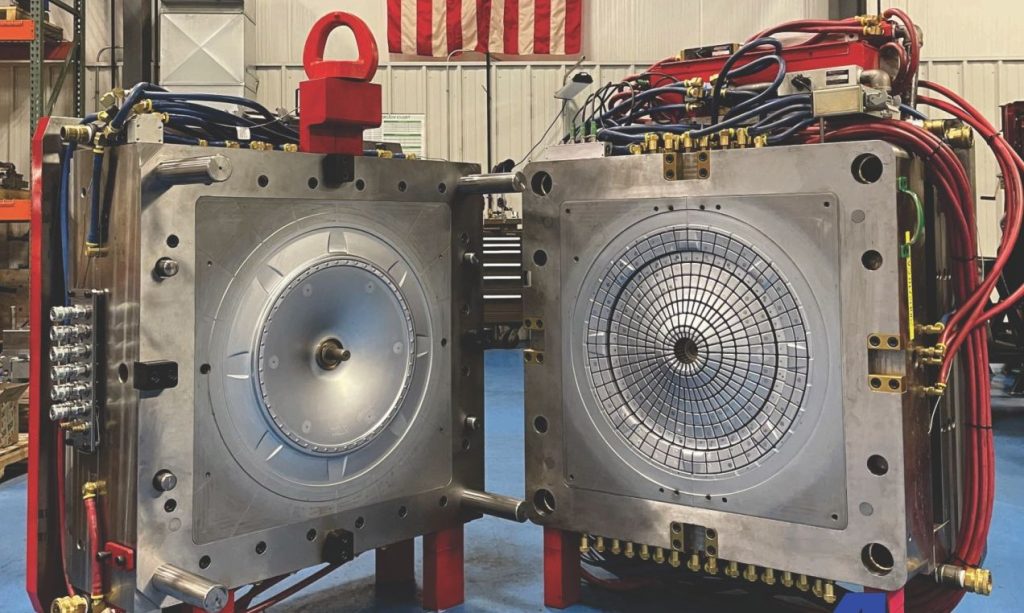

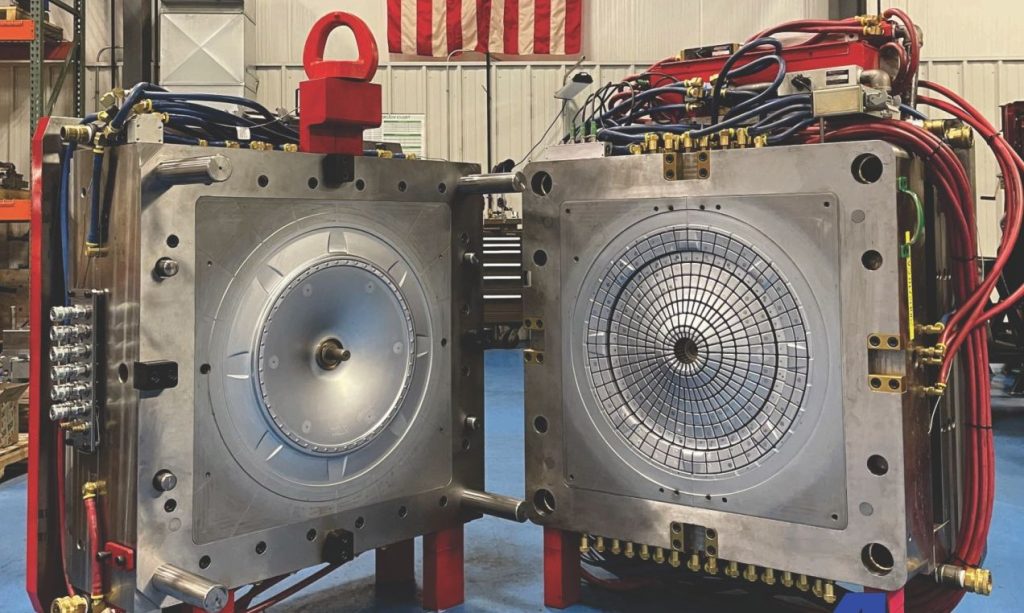

Tooling

Tooling

Manufacturers depend on engineered molds for packaging, automotive, and consumer products. Our molds meet the demands of high-volume production. And with additive manufacturing, you won’t waste money on unused material or molds that constantly break.

Industries We Serve

Defense

_____________________

Defense

We support the defense industry by creating advanced suppressors built to meet specialized needs, like handling 8,000 flawless rounds without cleaning. Powered by TruPore technology, our suppressors reduce heat, improve durability, and cut maintenance time.

Surgical

_____________________

Surgical

We engineer cutting-edge medical components, including bone-integrated implants and high-performance surgical tools featuring TruPore technology. By leveraging advanced additive manufacturing, we create lighter, stronger, and more efficient designs, reducing lead times and elevating surgical performance.

Tooling

_____________________

Tooling

Manufacturers depend on engineered molds for packaging, automotive, and consumer products. Our molds meet the demands of high-volume production. And with additive manufacturing, you won’t waste money on unused material or molds that constantly break.

Why Choose Next Chapter For Your Industry?

-

Engineering-Driven Problem Solving

We don’t just make parts—we engineer solutions. Every project benefits from our unique combination of advanced additive manufacturing, deep material science expertise, and real-world application insight. This ensures products that outperform traditional equivalents by up to 10x, whether it’s surgical tools, defense components, or injection mold tooling. -

Open Architecture Manufacturing for Customization & Performance

Unlike most manufacturers locked into closed systems, our open-architecture approach lets us source the best materials globally and fine-tune over 300 machine parameters. This freedom enables breakthroughs like aluminum suppressors that are 40% lighter with superior heat dissipation, conformal-cooled tooling that cuts cycle times, and surgical parts with unmatched precision. -

Proven Speed Without Compromising Quality

From prototypes to full-scale production, we deliver in days—not weeks. Whether meeting urgent defense contract deadlines, supplying critical surgical implants, or producing production-ready tooling, our rapid turnaround helps clients win more business and respond instantly to market demands.

Why Choose Next Chapter For Your Industry?

-

Engineering-Driven Problem Solving

We don’t just make parts—we engineer solutions. Every project benefits from our unique combination of advanced additive manufacturing, deep material science expertise, and real-world application insight. This ensures products that outperform traditional equivalents by up to 10x, whether it’s surgical tools, defense components, or injection mold tooling. -

Open Architecture Manufacturing for Customization & Performance

Unlike most manufacturers locked into closed systems, our open-architecture approach lets us source the best materials globally and fine-tune over 300 machine parameters. This freedom enables breakthroughs like aluminum suppressors that are 40% lighter with superior heat dissipation, conformal-cooled tooling that cuts cycle times, and surgical parts with unmatched precision. -

Proven Speed Without Compromising Quality

From prototypes to full-scale production, we deliver in days—not weeks. Whether meeting urgent defense contract deadlines, supplying critical surgical implants, or producing production-ready tooling, our rapid turnaround helps clients win more business and respond instantly to market demands.

Why Choose Next Chapter For Your Industry?

-

Engineering-Driven Problem Solving

We don’t just make parts. We engineer solutions. Every project benefits from our unique combination of advanced additive manufacturing, deep material science expertise, and real-world application insight. This ensures products that outperform traditional equivalents by up to 10x, whether it’s surgical tools, defense components, or injection mold tooling. -

Open Architecture Manufacturing for Customization & Performance

Unlike most manufacturers locked into closed systems, our open-architecture approach lets us source the best materials globally and fine-tune over 300 machine parameters. This freedom enables breakthroughs like aluminum suppressors that are 40% lighter with superior heat dissipation, conformal-cooled tooling that cuts cycle times, and surgical parts with unmatched precision. -

Proven Speed Without Compromising Quality

From prototypes to full-scale production, we deliver in days, not weeks. Whether meeting urgent defense contract deadlines, supplying critical surgical implants, or producing production-ready tooling, our rapid turnaround helps clients win more business and respond instantly to market demands.