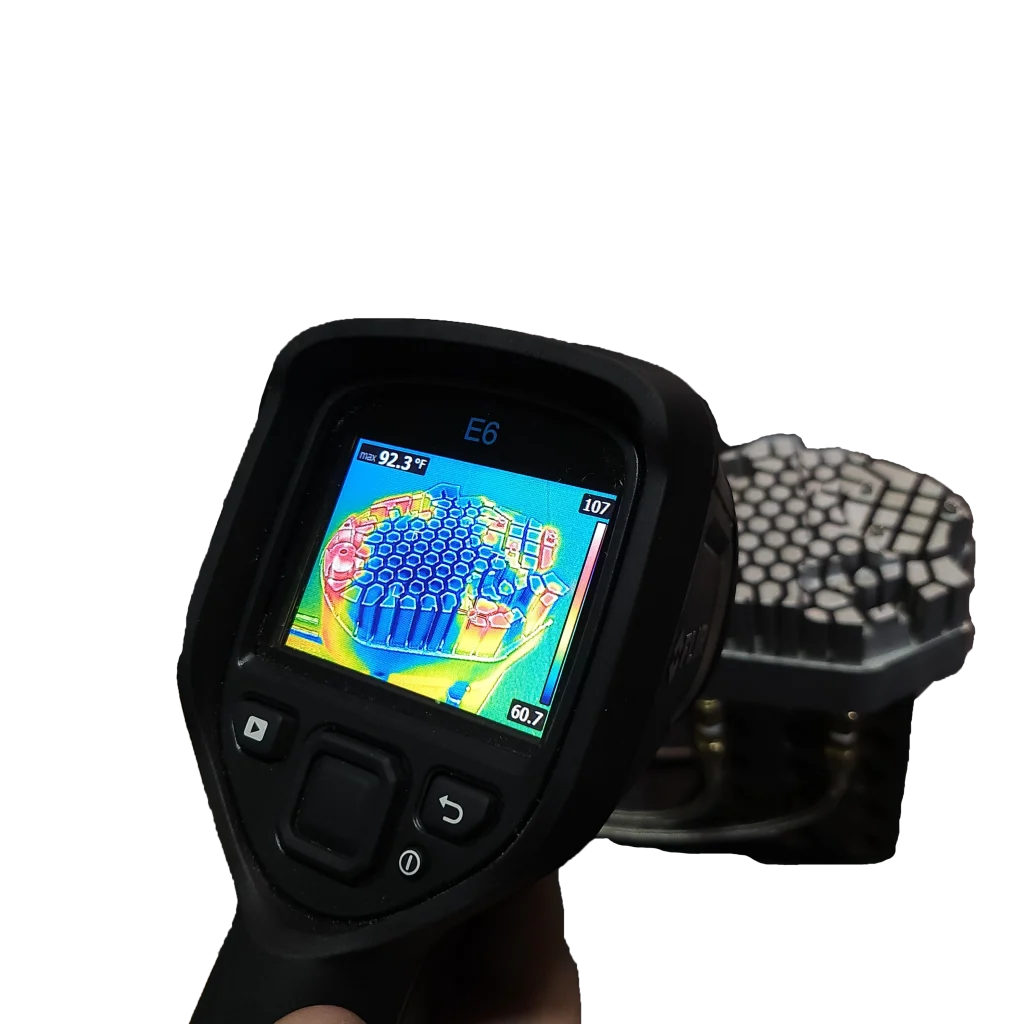

Mold Simulations Driving Measurable Improvement

Improve part quality and reduce defects with expert 3D printing analysis, including thermal and mold simulations built for performance.

Back Your Manufacturing Decisions with Data

At Next Chapter Manufacturing, simulation isn’t just a checkbox. It’s where design decisions become data-backed performance. We apply rigorous mold analysis to quantify exactly how much better your tooling will run with our solutions.

Why Mold Flow Simulations Matter

-

Data-Driven Insights

We compare conformal cooling designs against conventional setups to quantify reductions in cycle time, ensuring every design change delivers measurable benefits. -

Enhanced Cooling Meets Real-World Demands

Our focus on conformal cooling and heat optimization doesn’t just sound good on paper. It delivers performance in production. -

Optimized Tooling Performance

By refining cooling paths and simulating fluid dynamics, we help you achieve faster cycles, uniform part quality, and consistent results, turning engineering insight into manufacturing advantage.

Before

After

How it Works

-

Compare & Benchmark

We model your existing mold or tooling, then run simulations that directly compare it against conformal-cooled alternatives. -

Quantify Impact

Every design iteration is validated: cooling efficiency, cycle time reduction, and part performance are put under the microscope. -

Deliver Confidence, Fast

These insights accelerate design approval, reduce uncertainty, and de-risk production before the first shot hits the press.

Why Our Clients Rely on Mold Flow Simulation

-

ROI You Can Measure

We don’t stop at theory. We show you exactly how many seconds or cycles are gained through better cooling. -

Engineering With Integrity

Our simulations reflect real-world physics, not just “gut feel.” Expect precision in every channel and airflow path -

Seamless Integration to Production

From simulation to a finished mold, our analysis informs every step, making sure your tooling works right, from the first piece.